10 Loudspeakers Trends That Should End

As a loudspeaker reviewer, I get exposed to a lot of different

speakers over the course of a year, so I see a wide variety of practices

performed by speaker companies. Much of these practices are very logical as

would be expected of manufacturers with years of experience. However, some of

the things that these companies do are long overdue for an expiration. These

include marketing practices, design decisions, and logistical activities that

defy common sense or verge on the absurd. Here is a list of ten of these trends

in the loudspeaker business that I hope to see come to an end soon.

1.) Dual Binding Posts on

Normal Speakers

One engineering practice that is very often nonsensical is the use

of dual binding posts on normal home audio loudspeakers such as bookshelf

speakers and non-large tower speakers. By non-large tower speakers, I mean a

floor-standing speaker that doesn’t have a heavy-duty bass driver section that

could actually benefit from a serious amplifier beyond the standard one or

two-hundred watts or so that many of us have in our mass production AVRs. Are

you wondering if you have such a speaker? There is a good test that will let

you know for sure: if you have to ask, you don’t have one. Few people own home

audio loudspeakers with that level of capability like these monsters from Status Acoustics.

That isn’t to say that

your speaker won’t benefit from more wattage than what your name brand AVR can

supply, because many normal floor-standing home audio speakers could probably

take more power than what a typical AVR can give. Rather, bi-amping (and especially bi-wiring) isn’t the best way to

go about that. For starters, many users would be tempted to use different amps

to power the different sections of the speaker since they might have a spare

2-channel amp laying around with their AVR. The problem with that is that now

there is a good chance that the bass section of the speaker is no longer level

matched with the tweeter/midrange section. The only way to be sure that it

would be is to use the same amplifier on the same gain settings for both

sections of the speaker. What is more, many people would be tempted to use

their AVR to power one of the sections of the speaker, and that potentially

compounds the problem because there might be a processing delay on the

pre-amplifier outputs that can cause an extra latency on the bass section of

the speaker.

Some AVRs have settings that will enable them to be used to bi-amp

the main speakers, but the problem with that is it usually doesn’t grant you any more

headroom since the power supply is shared by the amplifier circuits for both

sections of the loudspeaker. The best approach is to just avoid bi-amping the

speakers and use an amplifier with enough power for the dynamic range that you

want.

So why do loudspeaker manufacturers put dual-binding posts in

So why do loudspeaker manufacturers put dual-binding posts in

speakers that do not realistically benefit from it? The answer is that it makes

the speaker seem fancier and it’s cheap to do. My wish is that they would drop

this pretense and just use a single set of quality binding posts for any home audio

speakers except for the truly massive ones. Dual binding posts are more often a

means of screwing up the set up of a speaker system rather than an opportunity

for an improvement in the sound.

Editorial Note by Steve

Feinstein:The

best way to bi-amp is to use two identical amps and use the L for HF and the R

of the same amp for LF. This guarantees perfect matching of amp gain, noise/THD

characteristic, etc. Per definition of bi-amping, as long as you’re still going

through the speaker’s internal passive x-o, you’re not really bi-amping.” This

whole thing is so bogus. Only external amps w/external active x-o’s count as

‘bi-amping.’As

I’ve written before in my ‘Insider’s View of

Product Development’ article,

there are lots of “customers”: The end-user, the store buyer, the store or

online salesperson, reviewers, etc. Some of their needs overlap, some do not.

“Bi-amp” terminals are mostly aimed at reviewers.But…..always

remember the 5x or 6x Cost-of-Goods-to-Retail price factor (also explained in

detail in that article). If bi-amp terminals and the larger terminal cup cost

the manufacturer an extra $5, then the retail will have to go up by $25-30 per

speaker.

2.) Small Feet on Big

Subwoofers

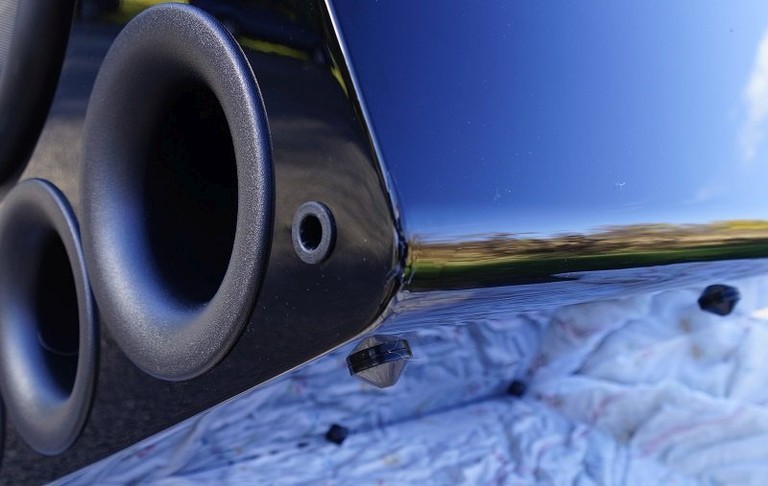

I review subwoofers as well as regular loudspeakers, and I have

had to deal with a slew of humongous subs that had feet that were too small for

the size and weight of the unit. Regular readers will know the manufacturers

that I am talking about because I do mention this problem in those reviews, but

I am going to name the worst offenders here anyway: SVS and Monoprice Monolith!

The shame of this is that these manufacturers make outstanding products

otherwise as we have seen, in review after review.

The main problem is the feet that they use on their large and

heavy subs do not offer as much clearance for fingers as they should for

lifting and lowering the subs on and off the floor. Both manufacturers in this instance use some small plastic conical feet that only give about a ¾”

clearance from the floor. While that might seem like just barely enough height

for fingers to get under, the problem is that these subs sink into a carpeted

flooring and can compress the carpet fiber so that there is very little space

between the sub’s cabinet and compressed carpeting. That creates a potential

pinch point for those who are setting the subs down on carpeted surfaces.

Among SVS’s subs, this becomes a real problem in the 4000 series

(except for the PC-4000) and 16-Ultra series subwoofers, since the weight of

all of those exceeds 100 lbs. Indeed, the weight of the PB-4000 is 153 lbs. and

the weight of the PB-16-Ultra is 174 lbs. It is not so bad with the 1000 Pro

series and 2000 Pro series since they are relatively lightweight. Monoprice’s

Monolith series, on the other hand, are all very massive subs; the 16” THX

Ultra is 171 lbs. And the M-215 THX Ultra is a staggering 216 lbs. I could

easily see any of these subs crushing someone’s fingers sitting on a dense

carpeted surface in a lowering-it-into-place accident.

Why do these manufacturers use such small, wimpy feet

Why do these manufacturers use such small, wimpy feet

on such giant subwoofers? The answer is that the subs look nicer when the feet

are not exposed. These feet are not really visible, especially on carpeted

flooring. What is more is that these have to be some of the cheapest feet to

buy in bulk quantities out there, so it is a win-win for these manufacturers.

However, in my opinion, these feet are a hazard for consumers. My

recommendation is that these manufacturers use feet that offer at least a 1”

clearance, but 1 ¼” would be better. That should give people adequate clearance

to safely lift and lower these subs on carpeted surfaces.

Editorial Safety Note: Use safe

lifting techniques with large speakers or subs!It only takes one bad

lift to cause serious damage to your spine that can lead to years or even a

lifetime of back pain! Always follow safe lifting practices for handling

speakers and subwoofers. Here is a good guide for safely

lifting these types of items, and here is a list of sensible tips. Always have someone help you lift a large subwoofer. If you

have to carry a large sub up or down a staircase, always use a dolly, even if

you have other people around to assist you. I always use a shoulder dolly strap

system with a buddy when I have to move a large subwoofer anywhere. You are

only given one back, so don’t play Russian roulette with it in order to save

some time or convenience on moving something heavy.

3.) Matte/”Satin” Finish

Confusion

Something that should stop (but is unlikely to) is when

manufacturers claim a “satin” finish on products that really couldn’t even

claim a matte finish. If you are purchasing a loudspeaker or subwoofer that

claims a satin finish, beware. In my experience, it is more likely to be a

textured vinyl finish unless you are paying for a premium item. These finishes

have well-defined meanings that have been blurred by marketing departments

trying to make the product appear nicer in brochures than they are in

actuality. Proper “satin” finishes are silky and very smooth and do have a

reflective sheen although a lot more diffuse than a gloss finish. A true satin

finish is smooth to the touch and has no texturing. A proper “matte” finish

should still be smooth but has very little light reflectivity or sheen. Matte

absorbs light. It would not properly have a rough texture though.

Textured vinyl finish- this is not satin!

In many instances, I have seen speakers that have a satin or matte

finish listed in the specs but in reality, the speaker has a textured vinyl

finish. That stretches the definition past the breaking point. These speakers

should just list “textured vinyl” in the specs as the finish. It is not as

glamorous, but it isn’t really all that bad either. The nice thing about these

textured vinyl speakers is that they are a much more durable finish than a

smooth satin or matte finish, and fingerprints don’t easily show up on them. It

would be a bummer for someone who is looking for an upscale appearance for the

product to order something promising a satin finish and end up with textured

vinyl, and it is due entirely to deceptive marketing. I would guess many people

are savvy enough to not expect a true satin finish on a set of speakers that

cost $200 even if it is listed in the specs, but a lie is a lie, and it should

come to an end.

A real satin black finish

If you are a speaker company and want to oversell your loudspeakers,

If you are a speaker company and want to oversell your loudspeakers,

just use the vague technobabble that means nothing in terms of loudspeaker

design but which we sometimes see in marketing anyway, such as:

“high-definition,” “HD-ready,” “audiophile-grade,” “reference-grade,”

“time-coherent,” “low noise,” “three-dimensional,” etc. At least that kind of

language can’t mislead since it contains no meaning to begin with. No need to

mislabel a specific kind of finish type.

4.) Not All Non-dome

Tweeters are “Ribbon” Tweeters

If we were to trust loudspeaker marketing departments, it would

seem that we are living in an era of a ‘ribbon’ tweeter renaissance. Where once

there were only dome tweeters for home audio speakers (with a few exceptions),

now we are flooded with an assortment of affordable speakers using “ribbon”

tweeters that claim a higher fidelity. Except they aren’t. True ribbon tweeters

are still relatively scarce and remain primarily on fairly pricey speakers.

They certainly can’t be found on any models priced less than $1k/pair. So what

then are all of these so-called “ribbon” tweeters on lower-cost loudspeakers?

Many tweeters being sold as “ribbon” tweeters are really either

AMT tweeters or planar tweeters, and all of these tweeter types have very

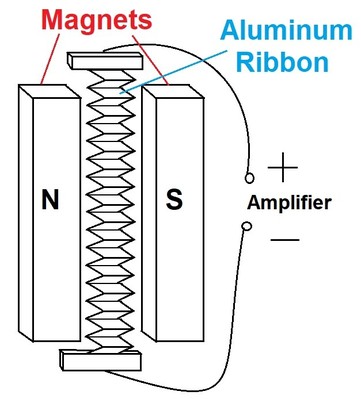

different methods of transduction. First, we have to define what a proper

ribbon tweeter is, which isn’t difficult, since mechanically speaking, it is

one of the simplest tweeter designs. Ribbon tweeters work by suspending a very

thin strip of aluminum between some powerful magnets. Alternating current is

sent through the aluminum strip, and the accompanying magnetic charge of the

electrically-charged strip whips it back and forth in the permanent magnet’s

field. The aluminum strip is so light that it can easily oscillate to very high

frequencies well above that of human hearing.

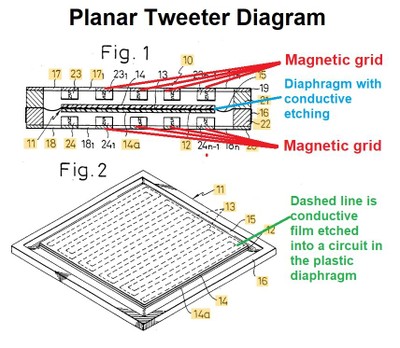

Planar tweeters work by printing a conductive film trace on a flat

plastic diaphragm that is usually rectangular in shape and then inserting that

diaphragm between grids of magnets. The conductive film trace is electrically

charged with alternating current, and the corresponding magnetic charge of the

electric charge is enough for the conductive film to move the entire diaphragm

back and forth very rapidly. A key difference between planar tweeters and

ribbon tweeters is that the charged element of the moving assembly in the

planar tweeter composes only a small fraction of the moving assembly, whereas

in a ribbon tweeter, the charged part of the moving assembly is the entire

moving assembly. Since the entirety of the moving assembly of a ribbon tweeter

is conductive, it doesn’t have much electrical resistance, so in order for it

to work with normal amplifiers, the resistance must be raised by a transformer.

So one way to identify a real ribbon tweeter is that it will always come with a

transformer.

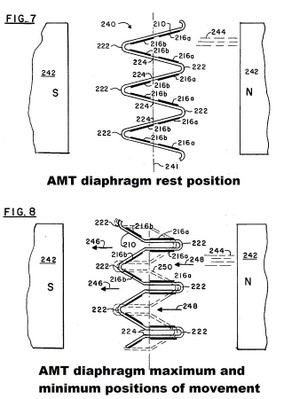

Air Motion Transducer tweeters, or AMT tweeters, work by creating

a pleated polymer diaphragm that is vertically lined with conductive aluminum

struts. This pleated or ‘folded’ diaphragm is set in a magnetic field, and when

the aluminum struts are charged with alternating current, the folds expand and

contract depending on the polarity of the current. The contraction of the folds

shoots air out, and the expansion sucks air back in. A major advantage in this design is that since it

is the folds of the diaphragm are much deeper than they are wide, the air is

ejected out much faster speed than the vibration of the diaphragm itself- as

much as five times faster. Much like a planar tweeter, AMTs do not need a

transformer to step up the resistance of the circuit. They are pretty easy to

discern the difference between true ribbons in that AMTs will have a wider

pleated diaphragm surface instead of a thin metal strip; if it has folds, it’s

an AMT.

These tweeter types don’t have all that much in common. However,

many loudspeaker manufacturers have decided to promote planar and AMT designs

to the status of ribbon tweeters since ribbons are typically much more

expensive and usually seen on higher-end loudspeakers. They are banking on the

public’s ignorance of the differences of these designs versus that of the much

more visually obvious difference between them and dome tweeters. The problem is

that words have actual meaning, and it is dishonest to blur the difference.

What is worse is that each has its own strengths, and  planar and AMTs can have

planar and AMTs can have

advantages over ribbon tweeters. So, there is no shame in using planar or AMTs

over ribbons, so long as the end design has good performance. While we are

discussing this subject, domes, rings, and compressions drivers all have their

strengths as well, so these flat plane diaphragms aren’t necessarily better

than round ones; it’s all a matter of achieving a good performance target.

My recommendation to manufacturers is to just call AMT and planar

tweeters what they are, and promote them for their respective strengths, which

are considerable.

5.) Not All Sealed

Loudspeakers are “Acoustic Suspension” (Almost None of Them Are)

There are many instances where loudspeaker manufacturers will

label their sealed design as “acoustic suspension” or even brag about their

high-fidelity “acoustic suspension” enclosure for more “accurate” or “tighter”

bass. However, those designs are almost never true acoustic suspension designs,

and they are almost always simple sealed loudspeakers. Our frequent contributor

Steve Feinstein wrote a great article going into detail about the design and

history of true acoustic suspension here: “Sealed is Not Acoustic

Suspension in Loudspeakers,” so I won’t go into much detail here, since it is well

worth reading his article. I will only briefly go over the definitions, so

readers understand the difference- and why true acoustic suspension speakers

are basically non-existent on the market today.

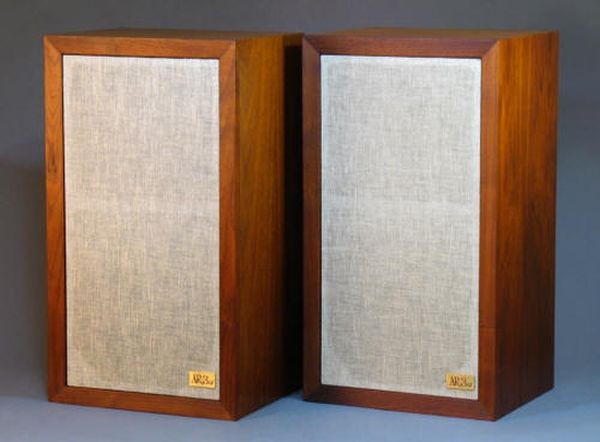

Acoustic Research AR-3a (1969)

Acoustic suspension has a lot to do with how the moving assembly

within the driver is controlled so that it has a healthy level of excursion

without needing a lot of power to move it. Acoustic suspension is defined as a

speaker where the restoring force for the bass driver relies on the air

pressure in the enclosure. In a typical driver in a typical speaker, the

restoring force lies in the motor and suspension components. In an acoustic

suspension system, air pressure forms a significant part of the restoring force

and more specifically the back spring pressure from the interior of the

speaker. That kind of system doesn’t need suspension with as much tension, so

it can be driven quite easily. There is a whole other host of advantages that

Steve goes over in his article. This design requires a delicate balance of

enclosure volume and driver specifications that just isn’t how modern

loudspeakers are engineered anymore, for better or worse. It’s a very different

system than an ordinary sealed loudspeaker.

Editorial Note by Steve

Feinstein:Air

is linear in its compression/expansion, much more so than a driver’s mechanical

suspension. Acoustic Suspension proponents claim that this linearity can give

AS systems lower distortion than other types, especially in lower-cost, small

systems. A $100 ported bookshelf speaker with a garden-variety 6 ½” woofer

likely won’t have the greatest mechanical linearity, but a properly designed AS

system of the same size/cost will have cleaner bass/lower THD because of the

air spring’s inherent linearity/regularity.

So why do loudspeaker companies still call their ordinary sealed

So why do loudspeaker companies still call their ordinary sealed

design “acoustic suspension?” I would guess that the reason is pretty much

simple ignorance layered with marketing gloss. Probably most people involved

with the marketing and promotion of loudspeakers do not know what an actual

acoustic suspension speaker is (not that being informed ever stopped marketing

departments from twisting the truth). Many of these people would be too young

to know about the original designs. And the misleading practice of calling

simple sealed systems “acoustic suspension” has just carried over from decades

past from those marketers who might have known the difference.

The solution to this is clear: just stop giving the label of

acoustic suspension to sealed loudspeakers. It’s not like the phrase “acoustic

suspension” has so much added dazzle since few people even know what it is

anymore.

6.) Mounting Tweeters

Away from Midrange/Mid-bass Drivers

One thing I would like to see change is having fewer speakers

where the tweeter is mounted a significant distance from the adjacent driver in

frequency bandwidth, whether that be a midrange driver or mid-bass driver.

There are exceptions where this is an OK practice, such as when the tweeter can

accommodate a low crossover frequency, but there are significant acoustic

penalties for setting the tweeter distant from the next lowest range driver.

The reason for this does take a bit of explanation, but when the tweeter is

closer to the midrange/mid-bass driver, it can be a significant benefit to the

speaker.

The reason why mounting the tweeter away from the

midrange/mid-bass driver is a bad thing is that the areas in which the signals

from those drivers integrate become much more narrow. The problem is that the

sound wavelengths in normal crossover frequency ranges to the tweeter are very

small, and if they are being emitted by two different sources that are spaced

apart, they will conflict with each other everywhere where the distance between

them is not the same. The further that the tweeter is from the midrange/mid-bass

driver, the greater the potentially conflicting bandwidth a loudspeaker can

have. Of course, this problem is contingent on the crossover frequency to the

tweeter, and if a tweeter can have a low crossover frequency, that can do a lot

to mitigate this problem. However, normal tweeters mounted flush on the

speaker’s front baffle can’t usually handle a low crossover frequency. Most of

them are crossed over between 2.5kHz to 3kHz. The wavelength of 2.5kHz is 5.4

inches. The distance of interest to us is the center of the drivers that

have adjacent bandwidths, and this is called center-to-center spacing. We do

not want the center-to-center spacing of the tweeter to the midrange/mid-bass

to exceed one wavelength of any of the frequencies near the crossover

frequency, and ideally, it should be a lot closer than that.

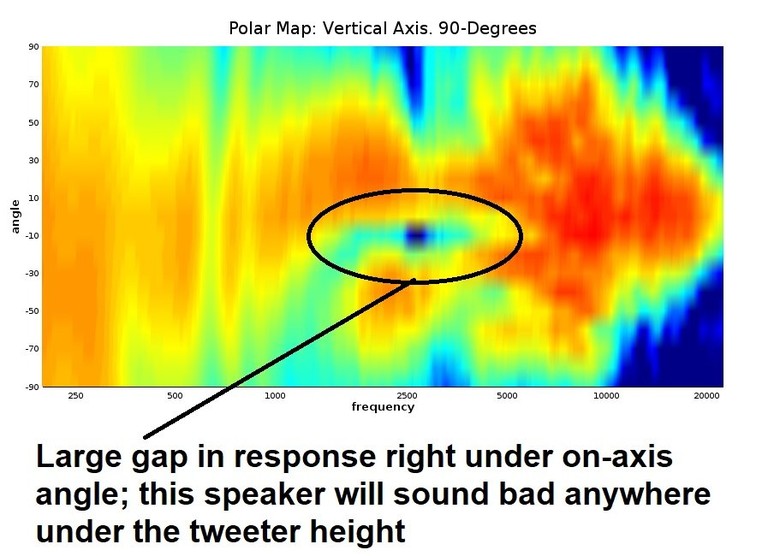

The result of widely spaced drivers is that the off-axis areas

where the sound waves will conflict end up becoming deep nulls where output is

totally canceled. These are called crossover nulls. This happens with any

spacing between the drivers, but the further the drivers are mounted from each

other, the worse it gets. When the drivers are close together, these crossover

nulls occur further off-axis and can be less severe, but with a far spacing,

the nulls can hang right around the on-axis angle, and that means that if you

aren’t listening dead on the tweeter axis at a far enough distance, a big chunk

of the sound will be gone because the sound from the tweeter is out of phase

from the sound of the woofer. What is worse is that the frequency band where

this usually occurs is an important part of the speech band, so this occurrence

can negatively impact dialogue intelligibility.

This is why I always find it to be a matter of careless speaker

This is why I always find it to be a matter of careless speaker

design when I see the tweeter set a good distance from the midrange driver.

What is also strange is that a lot of pricey “hi-fi” tweeters have large faceplates which necessitate a distant spacing. All that

does is make the loudspeaker very picky about placement. If you are listening

slightly above or below the tweeter height in such a speaker, you will be met

with a big hole in the response and a noticeably incomplete sound. What is

more, the vertical acoustic reflections are audible and can impact the sound,

so a poor off-axis vertical response may adversely color the sound as well. If

you are a loudspeaker manufacturer and have a tweeter mounted in a flat baffle,

get it as close to the midrange as possible. It needlessly makes the speaker

worse to put distance between them when it was possible not to.

7.) Packing Using

Styrofoam

Serious home audio loudspeakers tend to be somewhat large and

Serious home audio loudspeakers tend to be somewhat large and

heavy. I would guess that the average bookshelf speaker is around 15 lbs., the

average floor-standing speaker to be around 60 lbs, and an ordinary subwoofer

to be around 50 lbs. Sure, there are examples of each that are lighter, but

there are plenty of examples that are much heavier. Either way, since these

items can be pricey, good packing is warranted due to the size and weight. Many

Internet direct companies ship their loudspeakers in heavy-duty cardboard

packed using thick polyethylene foam blocks of at least a 1” thickness or more.

That is usually enough to protect the speakers through the major shipping

carriers’ delivery (usually, but not

always), and I would consider it the bare minimum. Many companies will

double box the speakers and use extra thick foam blocks that cover the entire

tops and bottoms of the speakers as well as a protective mid-section stand-off

block. Sometimes shipping can be very abusive, and I have received speakers

that were well-packed and still suffered shipping damage.

Once in a while, I receive a speaker that uses styrofoam for packing material. Usually, the styrofoam is broken

if not completely shattered. On a couple of occasions, it failed to protect the

product just through a single, one-way trip, and the product was damaged. It

simply is not a good enough packing material for anything with significant

weight. There is one famous loudspeaker manufacturer that is notorious for

their poor packing practices that I won’t name (hint: starts with a K and

rhymes with “lipsch”). The only speakers that styrofoam packing is adequate for

are very light ones of less than 10 lbs., and even then a good amount of

styrofoam is required to protect the items.

I get why some companies opt for styrofoam packing; it is much

cheaper than polyethylene foam. A lot of people probably don’t realize the cost

of safely shipping items like

loudspeakers. It is a lot and constitutes a significant chunk of the price.

Maybe some accountant crunched some numbers and found that the cost of

Maybe some accountant crunched some numbers and found that the cost of

shipping-related damages did not outweigh the savings on using styrofoam

packing, but that calculation ignores the feeling of disappointment of the

end-user who was looking forward to the speakers. Furthermore, presentation

matters, and it inspires more confidence in the buyers when they unbox their

loudspeakers and see good packing materials. It means that the manufacturers

consider their own products to be worth the extra expense and effort.

My recommendation: stop shipping anything over 10 lbs. using

styrofoam packing!

8.) Sending Massive Subs

and Speakers Through Parcel Shipping

Many high-performance subwoofers are necessarily large and heavy,

since, as a matter of physics, it is very difficult to get deep bass out of a

small enclosure (without tons of power, and

even then, it is difficult). However, that

complicates the logistics of moving them around inside the home and delivering

them to the user’s home. Extra care must be taken to safely get them into place

to avoid both personal injury and damage to the unit. No one should try lifting

a 100 lbs. speaker or subwoofer alone, not just because of the weight, but

because the size makes handling that weight very cumbersome. It takes a team

effort to lift these things safely. But how often do you see parcel shipping

delivery men work as a team? The answer is never.

Many parcel shipping services require their delivery people to

handle absurd amounts of weight as a single individual. Sure, they will pay lip

service by saying that they train their delivery personnel to use safe lifting

techniques, but the reality is there is no way for a single person to safely

tackle these packages — yet the delivery drivers are expected to do just that.

On too many occasions I have seen delivery drivers struggle to bring some

massive box to my doorstep (and yes, I do try to help them when I know

something big is coming). The only parcel shipping service that places a

reasonable limit on the weight of their packages is the USPS, which only allows

a max weight of 70 lbs. UPS and FedEx have 150 lbs. weight limits on packages

that can be delivered through their services, and that is way too much for a

single person. DHL’s weight limit varies by the type of service being used, but

the most common ones that are used to transport audio goods are ‘Economy

Select’ and ‘Express Worldwide’ which both have weight limits of 154 lbs.

Speaker manufacturers should be more cognizant of the realities of

shipping practices, and if a large and heavy package is being shipped, it

should be shipped on a pallet. Yes, it is more expensive, but if something is

sent through shipping that is too large for a single person to safely handle,

you can be assured that at some point, a single person will be asked to handle

it. These individuals will either put their safety first and handle the item in

a reckless manner, or they will put themselves at greater risk. I have known

multiple individuals who worked for FedEx and UPS who ended up with chronic

back problems. Yes, the people who work for these companies are supposed to

always use safe lifting techniques along with the proper personal protective

equipment, but with the kind of strenuous deliveries-per-hour requirements that

these employees have to make, safety can go by the wayside in favor of job

security. It is no mystery why all the major parcel shipping businesses have

scores of labor complaints against them.

My recommendation to speaker and subwoofer manufacturers is that

My recommendation to speaker and subwoofer manufacturers is that

if the people in product development and management who are normal healthy

adults have real problems safely liting one of their packaged products, they

should have consideration for the logistics personnel that work in these parcel

shipping companies and just send it on a pallet. It is the right thing to do.

Shipping companies have repeatedly proven that they do not put their employees’

health and safety first. It’s unfortunate that responsibility has to fall on

manufacturers and consumers, but it does. Pay the extra money to ship these

huge items on a pallet out of consideration for your fellow humans.

9.) Plastic Tabs in

Binding Posts

Some loudspeakers manufacturers put plastic inserts inside of the

Some loudspeakers manufacturers put plastic inserts inside of the

binding posts for some reason. They have to be removed before using banana plug

terminators. In some cases removing these tabs can be annoyingly difficult.

Harman is guilty of this, and I have seen this on Infinity and Revel speakers,

but I have also seen this done in some non-Harman brands. Why do they do this?

I can’t think of a single reason why this would have any benefit. Thankfully,

it doesn’t seem to be very common. Nonetheless, it should be nonexistent.

Loudspeaker manufacturers: stop wasting pennies on tabs for binding post

inserts! You tell them, Gene!

Editorial

Note by Steve Feinstein:The

reason for plastic tabs in binding posts is for CE (European) safety reasons.

The ¾” binding post spacing is exactly the same as the spacing for the round

spades on European AC cords. Plus, binding post holes will accept those round EU

AC spades. Some brilliant bureaucrat somewhere thought that people were going

to start plugging in toaster and TV AC plugs into speaker terminals. I don’t

know for the life of me what they thought was going to happen, but that’s where

those plugs originated—to prevent Euro AC plugs from being connected to speaker

terminals. The reason for their inclusion in North American loudspeakers: in

addition to the above, it’s so U.S. speaker companies don’t have to build and

inventory “domestic” and “European” speaker inventory. They build one variant

and ship it wherever.

10.) Sealed

Configurations on Large Ported Subwoofers

Many manufacturers of high-performance ported subwoofers have

decided to include the option for running the subwoofers in a sealed operating mode

by including port plugs as an accessory. The question I have is why? Why would

anyone buy a giant ported subwoofer but then decide not to take advantage of

the very thing that makes that huge size a necessity (their super-deep bass

extension)? The reason why those ported subs must be so large is so that the

enclosure volume can support the very low port tuning frequencies. In other

words, a big box makes deeper boom boom. Sealing the ports completely negates

the ability of the ported sub to produce big SPLs in low frequencies, and so it

negates the reason for the enclosure size to start with.

The only reason why sealing ports of a ported subwoofer could be

useful is in a small room that gets so much acoustic low-frequency gain (this

is called ‘pressure vessel gain’) that it massively blows up the low-end of the

in-room frequency response and produces a boomy or bloated bass sound. However, a better method of tempering the

deep bass is to simply EQ the response. That way you can get a nice in-room

response without losing the headroom that is granted by the ports. Many of

these subs come equipped with onboard ways of electronically reducing deep bass

output, as opposed to the physical method of closing a port. And the likelihood

of someone placing these huge subs in a small room is low- and if they do, they

probably want that excess deep bass.

It seems to me that subwoofer manufacturers do this because the

It seems to me that subwoofer manufacturers do this because the

foam inserts are cheap to include as an accessory and the manufacturers can

then claim more operating modes in the checklist of the subwoofer’s features.

But what is likely to occur is that those who don’t know any better may simply

leave the inserts in the port and run the sub like that unknowingly eliminating

most of the sub’s deep bass output capability. In other words, it is more

likely to be a source of confusion and thus suboptimal system setup. It just

shouldn’t be done, as there is very little benefit to this ‘feature.’ My

recommendation to subwoofer manufacturers: don’t bother with the inclusion of a

sealed operating mode in your ported subwoofers. The reality is that it doesn’t

do any good.

Conclusion

These are a few of the things that loudspeaker manufacturers are

doing that I wish would change. Some of them are worse than others, and this

isn’t even a complete list of the practices that ought to stop. I just figured

that 10 is a nice round number and kept it at that. Stay tuned to Audioholics

for more rants in the future just like this one!